Fasteners and Machining: Incorporating Precision and Stamina in Production

Fasteners and Machining: Incorporating Precision and Stamina in Production

Blog Article

Browsing the World of Fasteners and Machining: Techniques for Precision and Rate

In the complex realm of bolts and machining, the quest for precision and speed is a perpetual obstacle that requires careful focus to detail and calculated preparation. From recognizing the varied selection of bolt types to choosing optimum products that can withstand rigorous needs, each action in the procedure plays a crucial function in accomplishing the wanted outcome. Accuracy machining strategies even more raise the complexity of this craft, requiring a fragile equilibrium between technological proficiency and ingenious approaches. As we look into the approaches that can boost both speed and effectiveness in this domain, the interplay between high quality control procedures and operational excellence arises as an essential centerpiece.

Understanding Bolt Kind

When choosing fasteners for a job, recognizing the various types readily available is vital for ensuring optimal efficiency and integrity. Bolts are made use of with nuts to hold materials with each other, while screws are functional fasteners that can be utilized with or without a nut, depending on the application. Washing machines are essential for distributing the tons of the bolt and preventing damage to the material being attached.

Selecting the Right Materials

Recognizing the importance of selecting the right materials is vital in guaranteeing the optimal performance and integrity of the picked bolt types went over formerly. When it concerns bolts and machining applications, the product choice plays a vital duty in establishing the overall toughness, sturdiness, corrosion resistance, and compatibility with the desired atmosphere. Various products provide varying residential or commercial properties that can dramatically influence the efficiency of the bolts.

Typical products utilized for bolts include steel, stainless steel, aluminum, brass, and titanium, each having its distinct strengths and weaknesses. Steel is renowned for its high strength and sturdiness, making it suitable for a vast array of applications. Selecting the ideal product entails taking into consideration aspects such as strength requirements, ecological problems, and spending plan constraints to guarantee the preferred performance and durability of the fasteners.

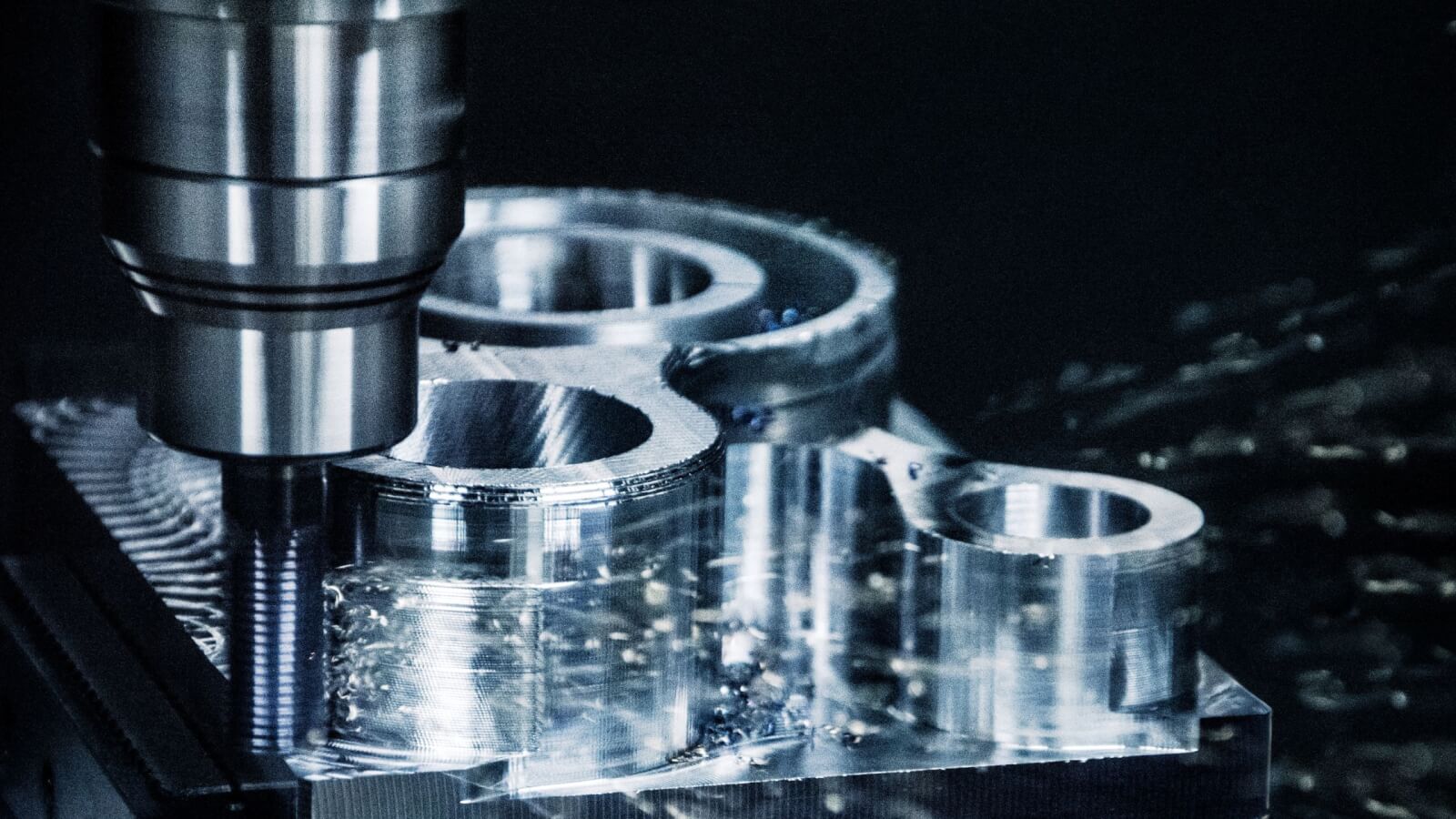

Precision Machining Techniques

Along with CNC machining, various other accuracy techniques like grinding, transforming, milling, and exploration play vital duties in fastener production. Grinding aids attain great surface coatings and limited dimensional tolerances, while transforming is often utilized to create cylindrical parts with accurate diameters. Milling and boring procedures are vital for forming and producing holes in bolts, guaranteeing they satisfy precise requirements and feature correctly.

Enhancing Speed and Performance

To optimize bolt manufacturing procedures, it is necessary to simplify operations and execute effective strategies that complement precision machining methods. One crucial method for improving speed and performance is the implementation of lean manufacturing concepts. By reducing waste and focusing on continuous improvement, lean practices assist get rid of traffic jams and enhance workflow. dig this Furthermore, spending in automation modern technologies can substantially improve production rate. Automated systems can handle repetitive tasks with accuracy and rate, enabling workers to focus on even more complex and value-added activities. Embracing Just-In-Time (JIT) stock administration can additionally enhance performance by making certain that the appropriate materials are readily available at the correct time, reducing excess inventory and lowering lead times. Promoting a society of cooperation and communication among group participants can enhance total effectiveness by promoting openness, problem-solving, and development. By combining these approaches, suppliers can accomplish a balance between speed and accuracy, ultimately improving their affordable edge in the fastener industry.

Quality Assurance Procedures

Carrying out extensive quality control measures is important in guaranteeing the integrity and uniformity of bolt items in the production procedure. Fasteners and Machining. Quality control measures incorporate various stages, starting from the choice of raw products to the final assessment of the finished bolts. This includes examining elements such as material structure, longevity, and strength to assure that the bolts fulfill market criteria.

Routine calibration of devices and machinery is essential to keep uniformity in production and make certain that bolts satisfy the needed tolerances. Applying rigorous methods for recognizing and addressing non-conformities or issues is vital in protecting against substandard products from going into the market. By developing a detailed top quality control framework, producers can promote the credibility of their brand name and supply fasteners that fulfill the greatest criteria of performance and resilience.

Final Thought

In the elaborate world of bolts and machining, the mission for precision and speed is a continuous obstacle that demands careful focus to information and critical planning. When it comes to bolts and machining applications, the material selection plays an important function in determining the total toughness, durability, deterioration resistance, and compatibility with the intended atmosphere. Accuracy machining includes various advanced methods that make certain the tight resistances and specifications needed for fasteners.In addition to CNC machining, other accuracy methods like grinding, transforming, milling, and exploration play crucial duties in bolt manufacturing.To maximize fastener production processes, it is crucial to simplify procedures and execute effective strategies that complement accuracy machining methods.

Report this page